The change from two-dimensional drafting to three-dimensional Computer-Aided Design (CAD) modelling marks a major change in approach in the modern des

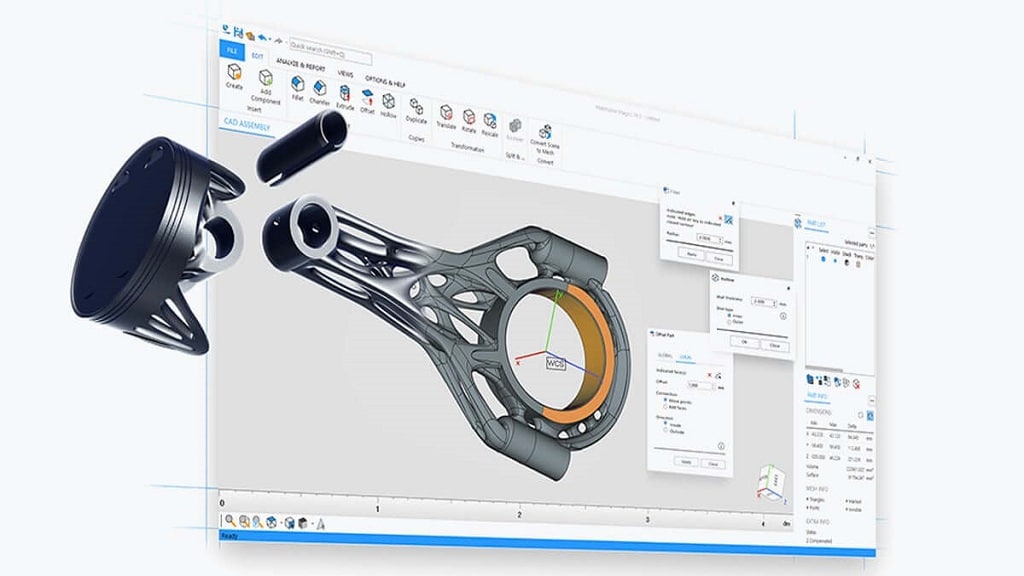

The change from two-dimensional drafting to three-dimensional Computer-Aided Design (CAD) modelling marks a major change in approach in the modern design and engineering scene. Unmatched improvements in speed, accuracy, and cooperation have been made available by this technology, which has transformed the product development approach. 3D CAD produces a dynamic digital prototype that may be visually examined, tested, and polished in a virtual world long before material assets are used, unlike static 2D drawings.

This initiative in problem-solving greatly lowers the chance of expensive mistakes and design flaws being found at the manufacturing step. Accessing this knowledge via specialised 3D CAD modelling services gives many companies a competitive advantage since it lets them use cutting-edge capabilities without significant software and training upfront expenditure. From first idea to finished manufacture, 3D CAD modelling ultimately simplifies the whole design process and promotes innovation under strict time and expense control.

Swift Conceptual Visualisation And Iteration

Designers can quickly convert abstract ideas into actual digital models using 3D CAD software. Designers can dynamically explore various forms, ergonomics, and assemblies to rapidly develop visual feedback-based versions. This dynamic approach speeds conceptual design by far more effectively than the conventional approach of producing several 2D drawings to reflect one modification. Phase and enable a more creative and investigative problem-solving approach without the cost of considerable revision.

Better Precision and Minimising of Errors

3D CAD modelling’s parametric and feature-based character naturally supports correctness. Geometries are constructed with logical dependencies, that is, a change in one parameter automatically updates all related while dimensions are defined mathematically. This removes the frequent manual coordination mistakes found in 2D drafting, where a change might be overlooked in one view, therefore causing inconsistencies. Moreover, the program can automatically identify components that conflict in the digital assembly before any physical model is created by performing interference checks and clearance analyses. Thus, guaranteeing design integrity and avoiding costly manufacturing errors.

Management of Streamlined Data and Cooperation

3D CAD models offer all project participants a single source of truth. All the necessary geometrical and metadata can be found in the same digital model, accessible and examined by engineers, designers, producers, and customers. Product Data and Cloud-based Platforms.. This focused strategy eradicates ambiguity from obsolete drawings, enhances communication, and guarantees everyone is in sync, therefore greatly lowering project delays and misinterpretation.

Direct integration with simulation and study

Modern 3D CAD systems automatically connect with Computer-Aided Engineering (CAE) programs. Directly on the digital model, this enables virtual testing and simulation. Engineers can examine structural integrity using Finite Element Analysis (FEA), evaluate fluid flow and thermal characteristics using Computational Fluid Dynamics (CFD), and undertake kinematic studies. To test the mechanism ‘sinding and correcting possible performance problems in the digital world, firms may greatly lower the quantity of physical prototypes needed, speed thespeed uppt’s time-to-market w,, while saving significant time and material expenses.

CAM’s Perfect Path to Manufacturing

Computer-Aided Manufacturing (CAM) and additive manufacturing (3D printing) use 3D CAD models directly to provide their digital basis. The CAD geometry is used for CNC machining to generate toolpaths that direct the machine exactly to cut the component. The model is sliced for 3D printing to create the physical item. From design to production, this digital thread guarantees the finished result is a replica of the digital intent, therefore reducing interpretation mistakes and simplifying the Going from engineering to production improves quality control generally and manufacturing efficiency.

Client Presentation And Effective Communication

For non-engineers than complicated 2D plans, a 3D model is a strong communication tool, much simpler to grasp. Photorealistic renderings, animations, and interactive CAD data can be used to generate virtual reality walkthroughs highlighting the product’s features and design. This helps customers and marketing departments to offer knowledgeable early input, guaranteeing the finished product satisfies market expectations and minimising risk. Late-stage changes are expensive and difficult to execute.

Lifecycle Management And Digital Twins Generation

Creating a digital twin, a virtual copy of a physical item that may be used for monitoring, maintenance, and future variations across its whole lifespan. Activities,,s including technical publications, service manual development, and spare parts planni,ng are supported by the rich data contained in the three-dimensional model. This long-term value helps effective upgrades, repairs, and end-of-life recycling approaches by means of the initial design expenditure continuing to pay rewards long after the goods have been introduced.

Conclusion

A definite best practice for attaining great design efficiency is the use of 3D CAD modelling. It helps quicker iteration, unmatched precision, and smooth integration across the whole product development lifecycle so profoundly and versatilely. It greatly lowers expenses and accelerates time-to-market by enabling early error detection, virtual testing, and automated documentation. Moreover, its function as a main communication hub guarantees all stakeholders are aligned and improves teamwork. Utilising the power of 3D CAD is a necessity for every company dedicated to surviving and flourishing in an ever more competitive and fast-paced environment, rather than just an edge.Towardd operational excellence, quality, and innovation.